Chapter 01

Uploaded by

Yash KanojiaChapter 01

Uploaded by

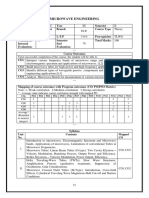

Yash KanojiaElectrical Machine II

EEEEC11 (3 – 0 – 2)

Semester 4

Chapter 01: Fundamentals of AC machine

winding

• Physical arrangement of windings in stator and cylindrical rotor; slots

for windings; single turn coil - active portion and overhang

• full-pitch coils, concentrated winding, distributed winding, winding

axis

• Air-gap MMF distribution with fixed current through winding

• concentrated and distributed, Sinusoidal distributed winding, winding

distribution factor

Electrical Machine

?

The electromechanical energy conversion process is a reversible one and simple

adjustment of the mechanical shaft and electrical conditions reverses the flow of power as

illustrated in Fig. 1.2. In this mode of operation, the electromechanical device, in general

called the electric machine, is known as the motor and the machine is said to be in the

motoring mode. Under steady speed operation, again TM (motor) = TL(load). Both in

generating and motoring modes, losses occur in the electric machine, but the overall

conversion efficiencies are very high (close to or above 90%).

A transformer is a static device that transforms electric energy from one ac voltage level to

another. It is this device that has made the electric system almost universally ac

Because the principle of rotating ac machines is akin to that of a transformer, these two are always studied together

in a book. Further, since the transformer analogy can be extended to both the ac machine types, the transformer

study usually precedes the machine study.

BASIC PRINCIPLE, TYPES AND CONSTRUCTIONAL FEATURES

OF ELECTRIC MACHINES

There are three basic rotating electric

machine types, namely

• 1. the dc machine,

• 2. the polyphase synchronous

machine (ac), and

• 3. the polyphase induction machine

(ac).

Three materials are mainly used in machine manufacture; steel to conduct magnetic flux, copper

(or aluminium) to conduct electric current and insulation to insulate the voltage induced in

conductors confining currents to them.

All electric machines comprise of two parts: the cylindrical rotating member called the

rotor and the annular stationary member called the stator with the intervening air-gap as

illustrated in Fig. 1.4. The rotor has an axial shaft which is carried on bearings at each end

located in end covers bolted to the stator. The shaft extends out of the end cover usually at

one end and is coupled to either the prime mover or the load.

The stator and rotor are both made of magnetic material

(steel) which conducts the magnetic flux upon which

depends the process of energy conversion

In both dc and synchronous machines, the main field is created by field poles excited with direct

current. The winding on the field poles is called the field winding. The relative motion of the field

past a second winding located in the other member induces emf in it. The winding interchanges

current with the external electric system depending upon the circuit conditions. It is this winding,

called the armature winding, which handles the load power of the machine, while the field

winding consumes a small percentage (0.5% to 2%) of the rated load power. The load dependent

armature current is known as load current.

SIMPLE LOOP IN

A UNIFORM

MAGNETIC

FIELD

1= single layer widing

Coil side per pole per phase

Coil side per pole

Formula

You might also like

- Electrical Machine II: EEEEC11 (3 - 0 - 2) Semester 4No ratings yetElectrical Machine II: EEEEC11 (3 - 0 - 2) Semester 4250 pages

- Lecture 1-Introduction to Electrical MachinesNo ratings yetLecture 1-Introduction to Electrical Machines19 pages

- 01a 02a PROT409 SynchronousGenerator 20230703No ratings yet01a 02a PROT409 SynchronousGenerator 2023070388 pages

- Electrical-Machines-2-AC-Machines-1-102No ratings yetElectrical-Machines-2-AC-Machines-1-10299 pages

- Basics and Working of AC Motors & Basics of Power GeneratorNo ratings yetBasics and Working of AC Motors & Basics of Power Generator37 pages

- Microsoft Word - CHAPTER 5 240311 105505No ratings yetMicrosoft Word - CHAPTER 5 240311 10550519 pages

- 21-Module IV Electrical Machines-21-03-2024No ratings yet21-Module IV Electrical Machines-21-03-202484 pages

- FALLSEM2024-25 BEEE102L TH VL2024250107060 2024-10-21 Reference-Material-INo ratings yetFALLSEM2024-25 BEEE102L TH VL2024250107060 2024-10-21 Reference-Material-I113 pages

- Lecture 06 - AC Machinery Fundamentals PDF100% (1)Lecture 06 - AC Machinery Fundamentals PDF34 pages

- Generalized Theory of Electrical MachinesNo ratings yetGeneralized Theory of Electrical Machines16 pages

- Chapter 3 - General Issues of Elec MachinesNo ratings yetChapter 3 - General Issues of Elec Machines31 pages

- Chapter 4 Introduction to Rotating MachinesNo ratings yetChapter 4 Introduction to Rotating Machines25 pages

- Principles of Operation: A Three-Phase Power Supply Provides A Rotating Magnetic Field in An Induction MotorNo ratings yetPrinciples of Operation: A Three-Phase Power Supply Provides A Rotating Magnetic Field in An Induction Motor5 pages

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other Essays5/5 (1)

- UV-Visible Spectrophotometry of Water and Wastewater Second Edition Olivier Thomas - The ebook in PDF/DOCX format is ready for download now100% (1)UV-Visible Spectrophotometry of Water and Wastewater Second Edition Olivier Thomas - The ebook in PDF/DOCX format is ready for download now50 pages

- Chapter 3 Transmission Line and Waveguide: Field Solution Field Solution (Cont'd)No ratings yetChapter 3 Transmission Line and Waveguide: Field Solution Field Solution (Cont'd)14 pages

- Ray Optics DPP 01 (Of Lect 01) - CH09DPP01No ratings yetRay Optics DPP 01 (Of Lect 01) - CH09DPP013 pages

- CBSE Class 12 Physics Question Paper 2022 Code 5511 Set 10% (1)CBSE Class 12 Physics Question Paper 2022 Code 5511 Set 112 pages

- Notre Dame University Louaize Faculty of Engineering ECCE DepartmentNo ratings yetNotre Dame University Louaize Faculty of Engineering ECCE Department6 pages

- Download full Terahertz Technology 2011th Edition Ali Rostami ebook all chapters100% (13)Download full Terahertz Technology 2011th Edition Ali Rostami ebook all chapters60 pages

- CLS ENG 21 22 XII Phy Target 3 Level 1 Chapter 7No ratings yetCLS ENG 21 22 XII Phy Target 3 Level 1 Chapter 713 pages

- Course Title: Laser Physics: Lecture # 4No ratings yetCourse Title: Laser Physics: Lecture # 419 pages